About UGHS for Paper Corrugation Machine

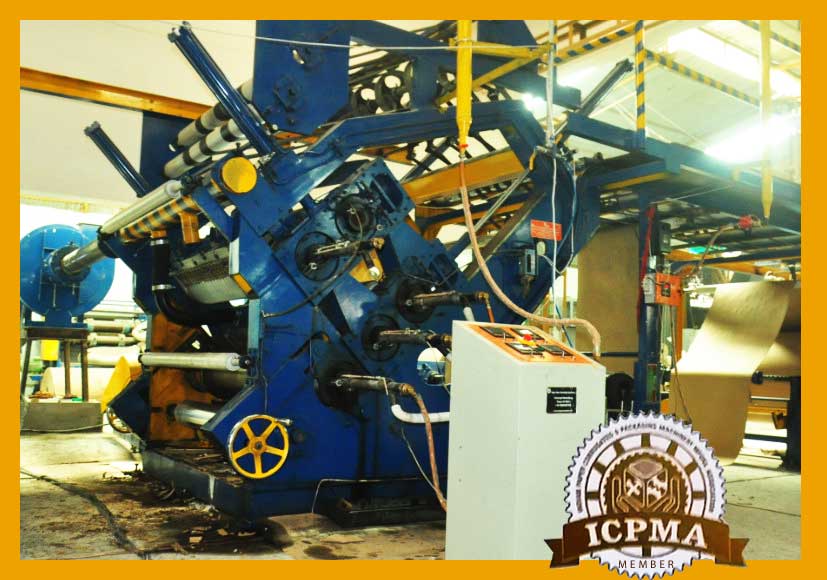

Paper Corrugation Machines

URJA Gas Heating System for Paper Corrugation Machines

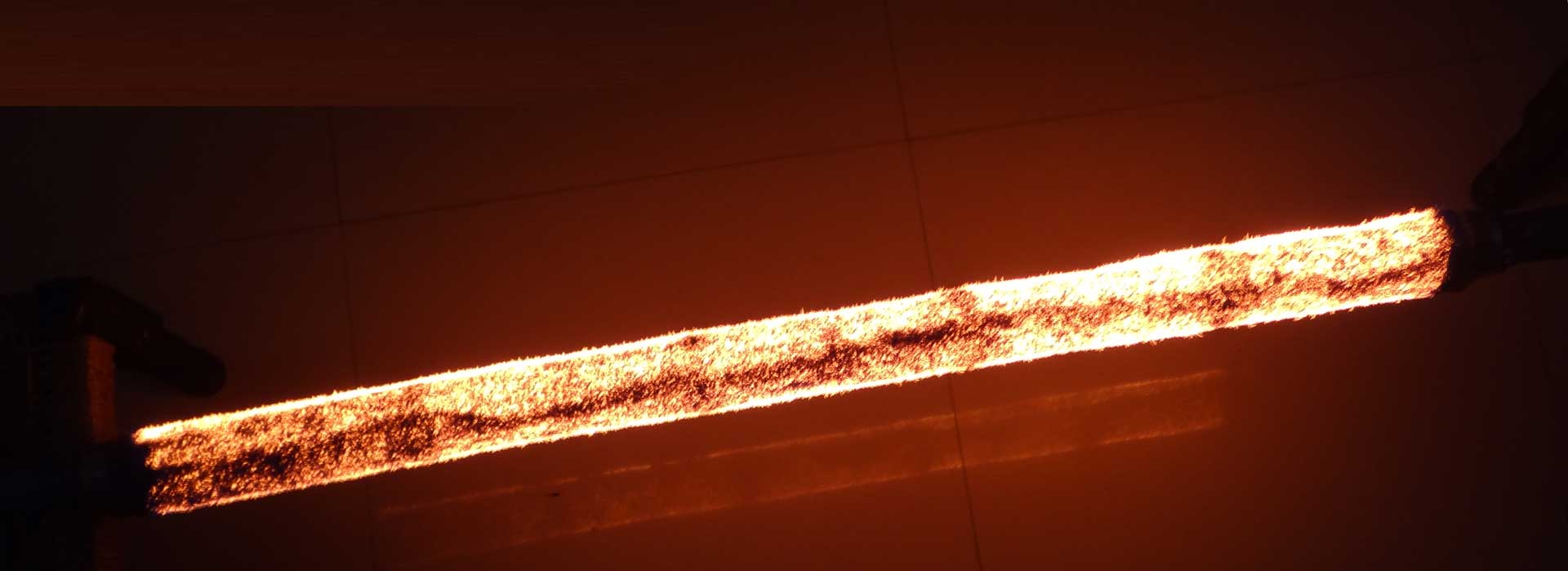

This system replaces the existing electric heaters / Oil / Steam heaters. This fully automatic system works on LPG and PNG. We have burners as per the machine size and are for Slow Speed as well as High Speed machines. For efficient burning forced ventilation system is also provided for these burners. The system is operator friendly. We also train the operator and maintenance staff on operation & maintenance of the URJA Gas Heating System during installation at site.

We have specially designed burners for this application. The burners are calibrated as per the heat input requirement and machine size. The gas entry is only from one side. Flame Sensor are fitted on burner to close the solenoid valve in case of no flame to ensure full safety. A digital Cyclic Timer is provided to trigger the gas control system independent for each burner. The Burner ON & OFF time can be easily set as per the site requirements. Minimum Roller ID (Inner diameter) required to fit the burner is 80 mm. This is required to accommodate the burner with proper gap when fitted in the roller.

We have installed this system on machines size from 32 inch to 80 inch flute size on Single Profile as well as double profile machines. A suitable Gas bank size depending upon the number of machines is essential for use of complete LPG. For PNG no Gas bank is required. The pipe line needs to be taken up to the machine. Burners for the pre heaters are also available as per the need. These pre heaters are different from the main burners. For installing pre-heater, the Roller ID (Inner Diameter) should be minimum 100 mm.

Order Now