Benefits of using Gas Heating Systems

Increased Productivity

Electrical load gets free

Less operating cost

Safe

Dependability

Long Term

Our Innovative Solutions

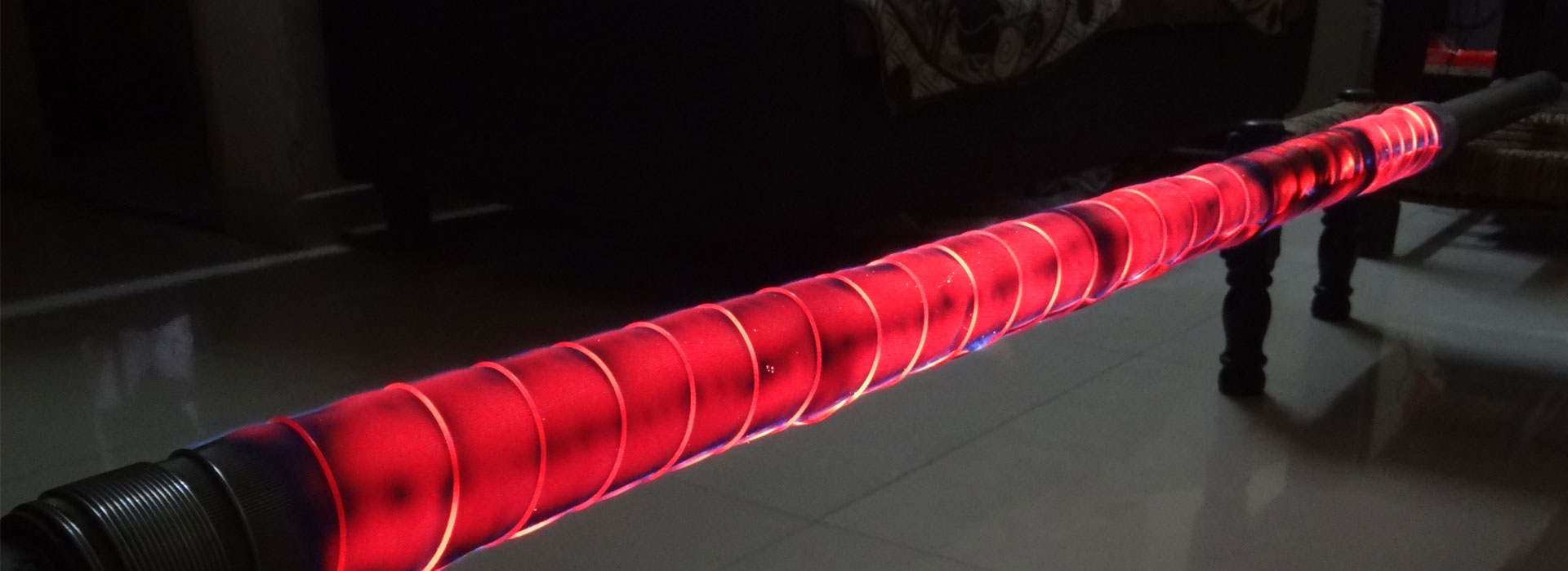

Paper Corrugation Machines

URJA Gas Heating System for Paper Corrugation Machines

This system replaces the existing electric heaters / Oil / Steam heaters. This fully automatic system works on LPG and PNG. We have burners as per the machine size and are for Slow Speed as well as High Speed machines. For efficient burning forced ventilation system is also provided for these burners.

We have installed this system on machines size from 32 inch to 80 inch flute size on Single Profile as well as double profile machines. A suitable Gas bank size depending upon the number of machines is essential for use of complete LPG. For PNG no Gas bank is required. The pipe line needs to be taken up to the machine.

- Increased Productivity

- Less operating cost

- Long Term lasting & Safe

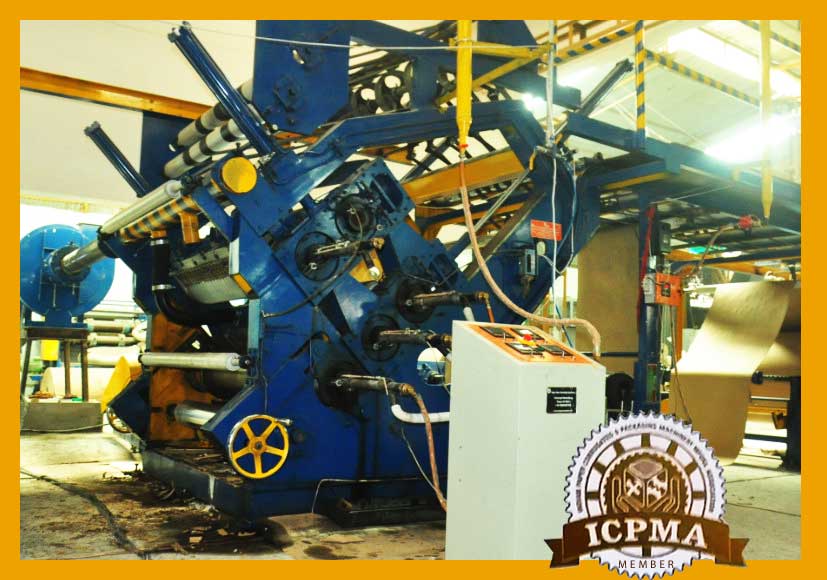

Gas Clothing Iron

Alernative to traditional electric commercial irons

In the ruler area the Laundry businessman had to use coal as a fuel for iron due to non adequate availability of electrical energy. To provide a very safe and eco friendly solution for these very people the thought of making an Iron which works on gas came ten years ago and further explored and this product was developed. The product went through various development stages and tried and tested.

This is for the commercial Laundry use. Safety of Man and the cloths is the top most priority. Today we have approx 8000 satisfied customers. We have also exported this product. The LPG consumption is very low and 200 to 225 cloths can be ironed in 1 Kg of LPG. The cost for ironing is as low as Rs 0.30 to Rs. 0.32 per Cloth.

- Works on ultra low gas pressure 300 mm of water column.

- Very easy to operate.

- The operation is exactly identical to the existing electrical Iron.

Injection Molding Machines

URJA Gas Heating System for : Injection Moulding Machines

This system replaces the existing electric band heaters fitted on the barrel and is operated on LPG. This system is fully automatic, safe and highly economical. We have made special heating arrangements using designed copper sleeve and cover to ensure uniform heating all over the barrel. The original machine PLC controller will be used For the nozzle heating, the existing electric heaters are used due to space constraints.

The system is operator friendly. We also train the operator and maintenance staff on operation & maintenance of the URJA Gas Heating System during installation at site.

- Increased Productivity

- Less operating cost

- Long Term lasting & Safe

Infrared Gas Burners

URJA Gas Heating System For: Infrared Gas Burners

We have developed various sizes of infrared burners and also tried on some application. These are indigenously manufactured and the performance has been found satisfactory. We make custom built gas infrared burners as per the requirement.

At present we have burners of various sizes like 250 x 40 mm, 300 x 100 mm, 400 x 100 mm, 600 x 200 mm, 1200 x 300 mm and 1250 x 40 mm 1400 x 300 mm burners.

- Increased Productivity

- Less operating cost

- Long Term lasting & Safe

Safe & Long Term

The system has auto ignition hence easy to fire the burner. The flame sensor fitted on the burner gives the feedback as soon as the burner is ignited and keeps the solenoid valve open.This ensures that no gas comes out of the burner.

Gets Electrical Load free

By taking care of the heating load which is a major contributor for the power requirement of corrugation machine, this electrical load gets free and more machines can be added with out additional electrical load.